According to the "In-mold Label Market Share and Scale Forecast to 2034" released by Future Market Insights, the global in-mold label market is expected to reach US$1.1339 billion in 2024, and sales are expected to maintain an annual growth rate of 2.8% from 2024 to 2034. Average compound growth rate (CAGR).

Among them, injection molded in-mold labels account for 70% of the market share, ranking first. It is expected to grow at a compound annual growth rate of 3.0% from 2024 to 2034. The food industry is the main application industry for in-mold labeling, accounting for half of the market share. It is expected that by 2034, the food in-mold labeling market will expand to 1.3 times its current size.

In the production process of in-mold label printing, the label curling, drying, and high static electricity after glazing have become key quality issues that affect the application of in-mold labels. Not only will it affect the appearance quality of the printed matter, it may also reduce the efficiency of subsequent processes and even affect the final user experience of the product. So what are the main factors that cause in-mold labels to curl and the ink layer to fall off easily after glazing?

01.In-mold label process characteristics

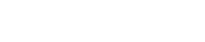

After application, the in-mold label is integrated with the packaging bottle and appears to be printed directly on the bottle body, giving a visual effect of "no label" without labeling seams. Because the solid adhesive on the back of the in-mold label integrates the label with the bottle body and is completely solidified, becoming a part of the bottle wall, the in-mold label generally does not suffer from edge bleeding or warping that is common with self-adhesive labels. , wrinkles, blistering and other labeling quality problems.

Comparison of in-mold labels and self-adhesive labels

In-mold labels are almost impossible to remove after application, unless destructive means are used, such as using a blade to lift the edge of the label and then peeling it off, or removing the label by heating the label edge. Once the label is torn off, the bottle body will also be destroyed, so the bottle body after applying the in-mold label is almost impossible to be counterfeited.

The in-mold label material is basically the same as the material used for the plastic bottle body. When the product is used up and the bottle body is recycled, the label can not be removed. The label can be recycled together with the bottle body and recycled again as recycled plastic. For self-adhesive labels, whether they are paper labels or film labels, when recycling bottles, the labels must be peeled off and then recycled, melted and recycled. The removed labels become industrial waste, which can easily cause environmental pollution.

02.The impact of coating quality on in-mold label application

In many printing processes of in-mold labels, glazing is an indispensable and important step to protect the ink and the smoothness of the label surface. Labels with a flat, smooth surface will not stick and separate easily when stacked. If there are quality problems with the in-mold label glazing, it will have a certain impact on the label application. If the label in the mold is bent, double or multiple labels will appear during the process of sucking the label into the mold, or the label will not be sucked and the label will be missed, causing damage to the bottle. If the labels are not completely dried after glazing, and the labels stick to each other, the labels will not come out during labeling or multiple labels will be sucked out at one time, resulting in labels falling off, bottle damage, and bottle blowing machines unable to produce normally. . If the glazing layer is too thin and the label surface is not smooth enough, it will also affect the separation of labels when the equipment absorbs labels.

03.In-mold label curling after glazing

Some in-mold labels will curl after glazing, that is, the labels will bend from the middle. A stack of labels will look like a tile and it will be difficult to separate them one by one. The main reasons for the curling of in-mold labels after glazing are as follows.

01

Glazing oil applied too thickly

The glazing oil should not be applied too thickly after in-mold label printing. The glazing oil film shrinks after UV curing, while the plastic film basically does not shrink. This results in inconsistent shrinkage rates between the two, which ultimately leads to the label bending and deformation (long direction). The shrinkage stress is greater than the short direction, causing the label to bend in the length direction).

02

Varnish material does not match

Another reason for the curling of the in-mold label may be that the glazing oil material is not matched or not used specifically. After curing, the shrinkage rate is too large, causing the in-mold label to curl. In addition, the bending deformation direction of the in-mold label is also related to the label size and material structure. Usually deformation occurs in the short dimension direction of the in-mold label, such as BOPP materials. But for uniaxially stretched materials, such as PP+PE materials, the deformation direction is generally perpendicular to the stretching direction.

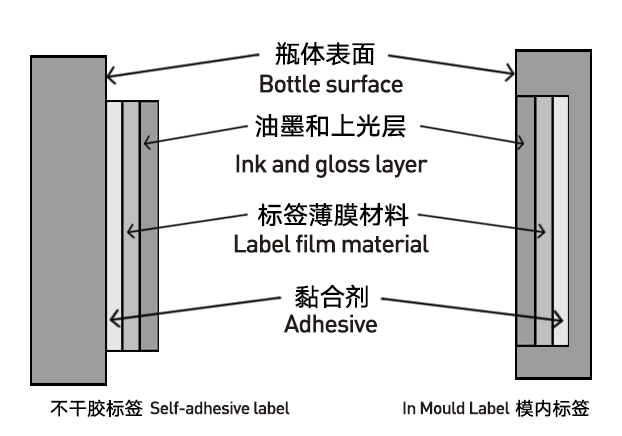

2022 Asia Label Awards Winning In-Mold Label Works

So, how to solve this kind of problem? First of all, you can choose an in-mold label material with good gloss or a glazing oil with a low shrinkage rate, and use a high-quality, scratch-resistant, special glazing oil that will not produce shrinkage and deformation to avoid bending and deformation of the label after glazing. Secondly, choose an anilox roller with a relatively small coating amount, 500~700 lines/inch, to replace the original anilox roller on the machine (usually 300~400 lines/inch).

04.After glazing, the ink layer is easy to fall off when touched.

The purpose of glazing is to better protect the ink layer. Why do some in-mold labels still have the ink layer fall off as soon as they are scratched after glazing? After glazing, the ink layer is easy to fall off when touched. There may be three reasons:

01

The ink is not dry yet

Apply varnish when the ink itself is not dry. After curing, although the varnish is dry, the ink inside is not completely dry. After the finished label is bonded with tape, the ink layer and the glazing layer will fall off at the same time. After drying, The varnish did not protect the ink.

02

Glazing oil too thin

When the varnish is too thin or a non-specific varnish is used, the varnish layer itself has no strength, so it cannot protect the ink layer. For example, the glazing method for some in-mold labels is offset UV glazing. Since the ink layer delivered by the offset ink roller is thin, the amount of glazing is also very small. If a special varnish is not used, the ink layer will be the same as the varnish layer. Touch the situation that is easy to fall off together.

03

Material has low surface tension

The surface energy of the material itself is low, that is, the surface tension value is low, which makes the ink and varnish less firm and can easily cause the ink to fall off.

When there is a problem that the ink is easy to fall off, you should first check whether the surface tension of the material is qualified (38 dyne). If it is not qualified, corona treatment is required. Secondly, ensure that the ink is dry before glazing, and finally check whether the strength of the glazing oil is qualified. In addition, the varnish can be water-based or oil-based infrared varnish and UV varnish that match the ink.

The above mainly introduces the process characteristics of in-mold labels, analyzes the causes of problems such as curling of in-mold labels after glazing, and easy shedding of the ink layer, and proposes solutions. To solve the problem of in-mold label glazing quality, we need to consider multiple aspects and conduct a comprehensive analysis based on certain practical experience.

Article source: @label Technology

Disclaimer: The content and pictures contained are from the Internet, WeChat public accounts and other public channels. We are neutral about the opinions in the article. This article is for reference and communication only. The copyright of the reprinted manuscript belongs to the original author and institution. If there is any infringement, please contact us to delete it.

+86 186 6517 1961