The in-Model Label is abbreviated as an IML) refers to the pre-printed paper, synthetic or thin film tags, and the back is coated with special hot-melt adhesives. Put it in the model before plastic blowing, injection or heat molding. , To generate plastic bottles or pots. The label and the container make up a whole. The label and the bottle body are basically on the same plane. The edge of the label cannot be seen, as if the graphic is directly printed on the surface of the bottle body. The label is no longer required to use the in -mold label. Therefore, the in -mold label is a new type of technology with great potential.

01

Manufacturing process in the mold label

1. Put a robot in the inner wall of the mold for label.

2. While the pre -forming plastic tube is inserted into the model, the vacuum holes on the mold will suck the label in the mold until the mold is completely closed.

3. The air is blown into the heated plastic pre -tube to make it full of space in the closed mold.

4. The heated plastic quickly expands and presses the inner wall of the mold, blows into a bottle, and fixes the label on the bottle.

5. The bottle after completion is removed from the mold.

The label in the mold is different according to the position of the posted, which is the trademark on the front or back of the package. The printed labels are placed in a single form, and the front labels and the back marks are placed in the two boxes of the labeling machine in the mold.

02

Materials in the mold

There are two main units in the world in the model in the model: the earliest entered the Chinese market is the Japanese Yupo in -label. This type of in -mold label material is quite good in the world. Now the label of Polyart (Priba) blowing molds has also entered the Chinese market. Some domestic companies are stepping up the label materials in the development of the mold. The materials in the mold are mainly divided into two categories: paper and plastic film. At the beginning of the label in the mold, the paper label with hot -melt rubber back layer was placed in the mold and bonded to the blowing bottle or melted into the bottle. Recently, for the purpose of recycling and performance, such as Polyart or Synteape -type synthetic paper materials. All in -mold label materials must have a good flat flatness so that there will be no failure when entering the blowing of the injection molding machine.

1. paper category

The surface of ordinary synthetic paper is poorly smooth, the strength of the intensity is relatively low, and the volume of low elasticity is small. It is difficult to high -end color printing, which is suitable for large -scale application methods of barrels. The paper label is easy to deform and reduce the value of the use of water. However, it is less affected by static electricity when used, and the loss when blowing the bottle is less loss. The paper label and plastic bottle are not homogeneous materials that are not conducive to the recycling of the bottle.

2. Film material

It is a special multi -level co -squeezing material, and the surface can be printed in a variety of printing methods. During the label processing process, the problem of inconsistency and mold cutting will not be caused by deformation. Some film materials can stretch, shrink and deform (such as Primax, Fasclear, etc.), which can be deforming with the shape of the bottle body on the bottle body, and label wrinkles will not appear after completion of the surface of the bottle body. The surface of the film does not absorb ink on the surface, so the labeling color printed on the film material is bright, three -dimensional, and the color effect is significantly better than paper materials. It is suitable for high -grade color printing and applications that are generally suitable for various exquisite products. PE, PP or PE and PP synthesis.

The in -mold label requires good printing suitable performance, so that the ink is firmly attached to the surface of the material. In the post -processing process, there must be good processing adaptability, which is suitable for mold cutting and cold bars processing. The in -mold label material must also have good use characteristics, which can be combined with plastic bottles when blowing plastic forming. The structure of the internal labeling material consists of the printing surface, the middle layer and the coherent layer. The role of the printing surface is to accept ink to form color graphics; the middle layer supports the printing surface, giving the material sufficient stiffness and transparency, and does not deform under high temperature on the printing machine to ensure accurate the cover; the adhesive layer is melted under high temperature action at high temperature. , Make the label material and plastic container into one -in -one to ensure that the label and the plastic bottle are firmly glued.

There are generally three printed facial materials: PE, Bopp and PE+PP. At present, most of the plastic containers are made of PE, so the use of PE -modal tags is more conducive to recycling and reuse. When labeling in the printing mold, in order to improve the introspection of the printing surface material, the surface coating is generally required or using the electric halo discharge method to improve the surface energy.

There are two structures on the surface of the gluing layer: plane -free grid structure and mesh structure. When using a web -free structure, it is suitable for small -area labels when using the rough natural exhaust. The mesh structure refers to the adhesive layer of the mesh structure on the surface of the adhesive layer. When labeling, the gas between the label and the bottle body exhausts through the exhaust channel of the mesh pattern. The production of bubbles is reduced, and the gum dry layer also has anti -static. To prevent double Zhang Zhang during printing; the adhesive layer should also have a certain degree of slide to ensure that the label is separated to make the printing process smoothly.

03

Model labeling method

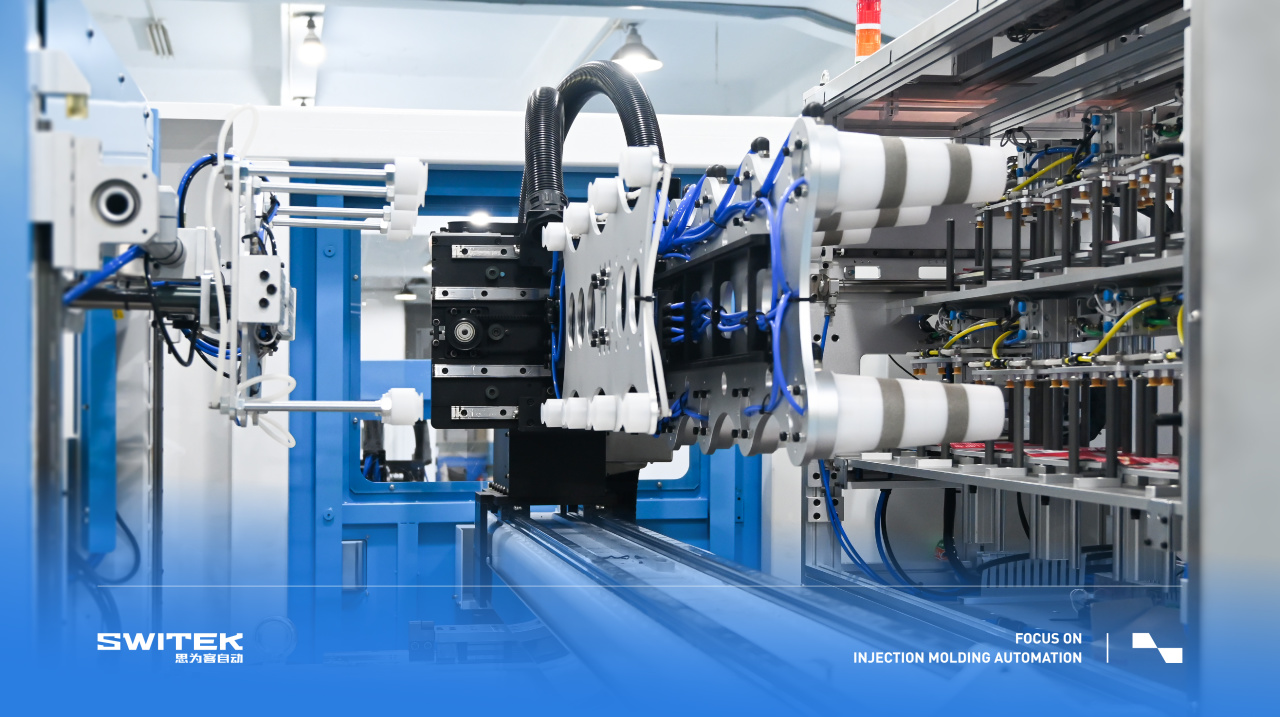

After the mold cuts into labels, the robot is put into the mold cavity with the robot, and the squeezed plastic temperature and the inhaled air pressure melt the label and the plastic bottle. Now, there are two ways to label in the chess: vacuum negative voltage mold suction method and static electrician suction method.

1. Vacuum mold suction

Vacuum molding is a relatively common method. Add a few real emblems to the original mold. Special equipment without casting, low cost, good use effect, and it is not easy to notice that vacuum stamps. The technology is currently very mature.

2. Static electric mold suction

The electrostatic mold suction method can also realize the in -mold tags. The advantage is that there is no need to modify the original blowing equipment. However, I haven't seen such equipment in China. The electrostatic mold suction method requires the following characteristics of the physical properties of the technical equipment and labels in the mold.

A. To add a high -voltage electrostatic occurrence system to the device, apply sufficient static charge to the label in a short period of time, and put the label on the inner cavity of a zero -potential blowing mold through the robotic arm.

B. The static electricity elimination system should be added to the device to eliminate the residual static electricity after each labeling to avoid affecting the electrical control system of the in -mold labeling machine and the label adhesion caused by electrical electricity.

C. There are requirements for label vertical materials and printing oil.

04

Comparison of the in -mold label and traditional label

The traditional labels corresponding to the use of the in -mold label are mainly 3 types: thermal contraction tags, direct online printing labels and adhesive labels (mainly non -drying labels).

1. Direct online printing labels are printed on the pattern and text printing on the container packaging. The overall effect is good, but the quality of the direct screen printing is not ideal. It is difficult to reflect the exquisite patterns and small text. The price of direct online version of the color is more expensive if the colors are more. The cost of direct online printing when the label color exceeds 4 colors is the most expensive of the three traditional label printing methods. From the perspective of the cost of label material, the label in the mold does not require the bottom paper, so the material cost has a certain decline room.

2. Use thermal contraction membrane (mainly PVC film) as a packaging label. The cost is much lower than the cost of non -drying label and direct online printing label, but the thermal contraction label is easily damaged. The overall shape is not good. Environmental friendly.

3. The adhesive label (mainly a thousand glue labels) is exquisitely printed, but the cost is more expensive than the thermal shrinking membrane label.

05

Advantages of labels in the mold

1. Novel and beautiful appearance:

The in -mold label and the plastic bottle are naturally touched, inlaid firmly, the label changes with the shape of the bottle body. The corner of the label cannot be seen on the plastic bottle, and the appearance looks beautiful. There will be no phenomenon such as foaming, wrinkles, etc., which can fight against twisting, scraping and pollution in the production and transportation process, so that the label can be complete and beautiful for a long time. In the humid environment, labels will not be raised or moldy. The feel is smooth, especially for daily chemical products with labels as the main packaging.

2. Good print performance:

The label printing effect in the mold can print the design patterns with rich details and delicate pictures, and has a strong visual expression. The in -mold label can reflect the exquisite patterns and small text of non -gum labels, and have the overall effect of direct screen printing, and the common direct network printing labels with fine circles are not easy to achieve.

3. Safe and environmental protection:

The label in the mold has the performance of waterproof, oil -proof, acid -resistant, friction resistance, frozen, soaking, soaking, and has good chemical stability. Precision and accurate labels can not only maintain the integrity and beauty of labels for a long time, but also are also beneficial to environmental protection. Unlike the heat shrinking label, it is easy to damage.

4. Cost advantage

If the number of printing is large, the internal label will be lower than the cost of non -dry glue label, and the cost of the printing color of the printing color is also lower. The cost of adding labeling equipment or labeling workers has shortened the production cycle and improved production efficiency.

5. Anti -counterfeit function:

The internal standard craftsmanship and mold are relatively complicated, and the production is difficult. It requires robotic operations. Compared with non -drying labels, anti -counterfeiting is stronger.

With these characteristics, the internal label process can meet the requirements of the same materials as the same material as the container (such as the PP label on the PP container) that the high -quality, low -weight container precision labeling is conducive to the recycling of the bottle body, which is beneficial to environmental protection is beneficial to environmental protection. Essence

06

Limitation of the label in the mold

1. If the in -mold label is not satisfied with the printing or labeling process, it will cause the bottle body and label dual waste.

2. Using the in -mold label requires expensive molds, special container blowing plastic or injection molding equipment, which makes the in -mold label cannot be easily accepted in the market. The relatively large number of printing in the mold label can reduce the process cost, and it is not suitable for applications such as short version of work and rush label manufacturing.

3. If a container made of blowing plastic process is used, if an in -mold label is used, the shape of the container must be considered "curvature." If the container is too large as a round bottle, it will cause difficulty in exhausting in the mold.

4. The in -mold label requires special mold -cutting equipment and electrostatic treatment during printing and processing, so the cost of printing and processing may be higher than that of traditional tags.

07

Uses of labels in the mold

The labels in the mold now are widely used in packaging of various plastic materials, such as HDPE, PP, PET and PS. It is mainly used in a one -time forming trademark of the hollow blowstration bottle:

1. Care products such as shampoo, conditioner, bath solution, bath milk, and personal care products that often contact water;

2. Laundry products such as washing essence, laundry fluid, laundry essence, kitchen cleaner, pollutant, etc. often exposed to water and decontamina.

3. Lubricating oil, refined oil, gear oil, antifreeze, chemical raw materials, pesticides and other large capacity blowing plastic stabs and explanation of firing containers.

4. Food container. Such as dairy products, ice cream, condiments, salad oil, soy sauce, vinegar, coffee, fruit juice, tea beverages, yogurt and other long -term frozen or tagged plastic barrels, bottles, boxes and instructions.

5, pharmaceutical industry, packaging of high -end drugs.

The label in the mold is moving towards recyclable pre -labeling containers, increasing the speed of loading, increasing container filling, improving appearance and better squeezing performance. As countries have begun to attach importance to environmental protection, the in -mold labels are expected to develop rapidly in the next few years after improving the process and reducing production costs.

Article Source: Network

Disclaimer: The contents of the contained, pictures are from public channels such as the Internet, WeChat public account, etc. We have a neutral attitude towards the views in the article. This article is for reference and communication only. The reprinted manuscript copyright belongs to the original author and institution. If there is any infringement, please contact us to delete.

+86 186 6517 1961