Disposable plastic cutlery, forks, spoons and tableware usually need to be packaged in BOPP film due to their strict production technology and process control, dust-free sterilization, and elimination of secondary pollution. In response to such needs, Siweike has rich application solutions and technical experience, and has launched a plastic table fork multi-pack packaging automation system that can perfectly solve such needs.

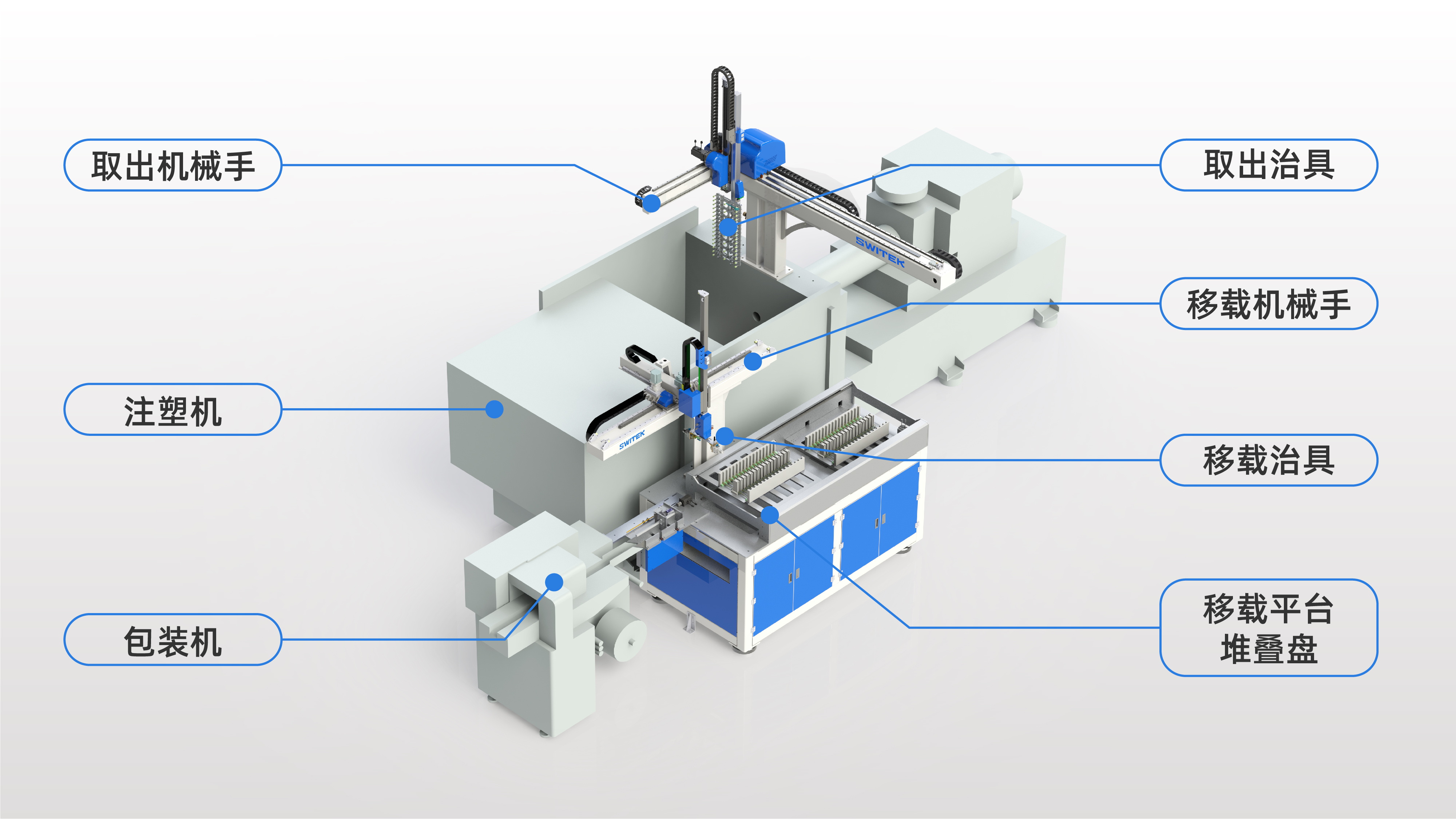

SWITEK plastic table fork multiple packaging automation system mainly includes the following parts: take-out robot, take-out jig, transfer robot, transfer jig, transfer platform, stacking tray, and packaging machine. The injection molding and multi-pack packaging of plastic forks are fully automated, which can quickly help companies realize automated production, reduce costs, increase efficiency, and create value.

Highlights of SWITEK plastic fork multi-pack packaging system:

Reduce costs and increase efficiency: fully automatic operation, saving manpower

Efficient quality assurance: from injection molding to packaging, automatic completion, high yield rate

Safety and environmental protection: no secondary pollution, safe and secure

Plastic fork multi-package production case

Product: 50 forks in bag

Material: PP

Number of mold cavities: 32

Cycle period: 10S

Manipulator model: SW6712DS (removal); SW7110S (transfer)

+86 186 6517 1961