Due to policy support and the rapid development of urbanization and industrialization, domestic plastic pipe production grew rapidly from 2000 to 2013, with the growth rate remaining above 10%. Although the plastic pipe industry has entered a period of stable development with the slowdown of urbanization in recent years and the normalization of the epidemic, it still has an annual growth rate of about 2%. Specifically, in my country's plastic pipe production, PPR pipe fittings account for about 10%. In response to the demand for automated production of insert joint PPR pipe fittings, Siweike has a three-axis/five-axis servo manipulator as the core to adapt to the market The pipe fitting embedded nut automation system solution for most injection molding machines can quickly help pipe fitting companies achieve automated production, help companies reduce costs and increase efficiency, and seize the market.

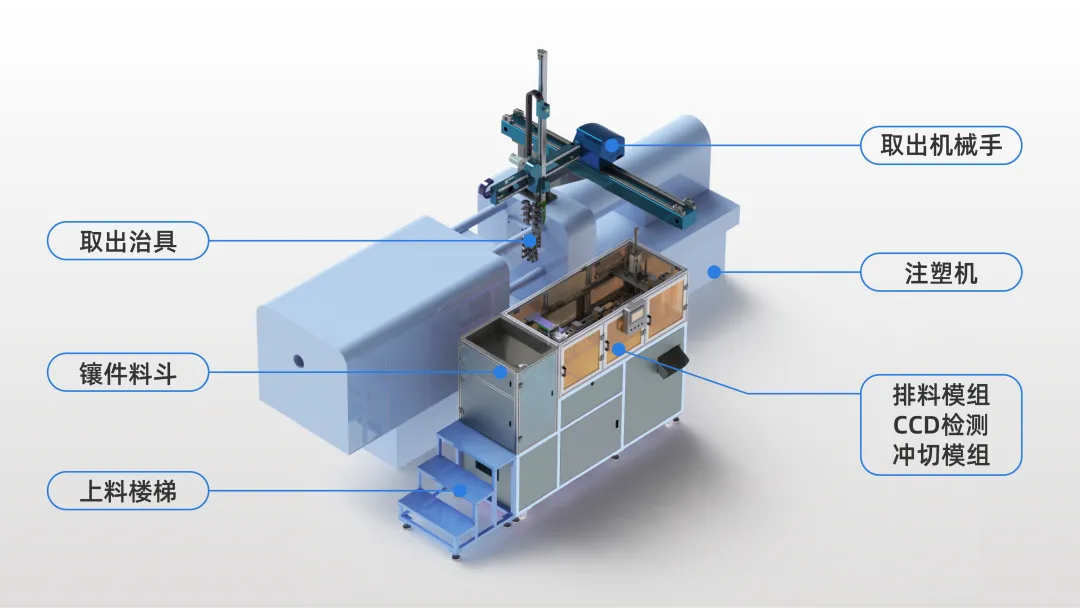

SWITEK pipe fitting embedded nut automation system mainly includes the following parts: taking out manipulator, taking out jig, injection molding machine, discharging module, punching module, detection module, material distribution and collection. It has realized a series of automated operations from nut discharging to embedded parts, injection molding removal, nozzle punching, finished product inspection, finished product and nozzle classification collection, and the production process is fully automated.

Highlights of SWITEK pipe fittings buried nut automation system:

Reduce costs and increase efficiency: fully automatic operation, saving manpower

Efficient quality assurance: finished product visual inspection, abnormal elimination; nozzle punching, high stability

Easy to control: PLC control, touch screen display, easy debugging

Elbow pipe fittings buried copper automated production case:

Product: Elbow fittings

Material: PPR

Number of mold cavities: 8

Molding cycle: 120s (+/-15%)

Manipulator model: SW6712DS-20

+86 186 6517 1961