Injection molding machine, also known as injection molding machine, injection machine and beer machine, refers to the main molding equipment that can make thermoplastic or thermosetting plastic into plastic products of various shapes using plastic molding molds. Injection molding machines usually consist of injection system, mold clamping system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system, etc.

According to the "China Injection Molding Machine Industry Development Status Research and Investment Trend Forecast Report (2022-2029)" released by Guanyan Report Network, injection molding machines have multiple classification methods. According to the difference in driving mode, it can be divided into hydraulic injection molding machine, electric injection molding machine and electro-hydraulic hybrid injection molding machine; according to the difference in material plasticization method, it can be divided into screw injection molding machine and plunger injection molding machine. The mixing performance of the machine and the quality of residual plasticized raw materials are better than those of the plunger injection molding machine.

According to the different axis directions of the injection and mold clamping devices, they can be divided into horizontal injection molding machines, vertical injection molding machines and angle injection molding machines; according to the different clamping force, they can be divided into large injection molding machines, medium injection molding machines and small injection molding machines. ; According to the plasticization method, it can be divided into plunger-type plastic injection molding machines, reciprocating screw-type plastic injection molding machines, and plunger-type plastic injection molding machines. Among them, screw injection molding machines are the mainstream in the market; horizontal injection molding machines are the most commonly used type.

Market development status

The downstream application fields of injection molding machines cover household appliances, automobiles, building materials, medical care, home furnishing, 3C, packaging materials and other plastic products industries. According to the China Plastics Machinery Industry Yearbook, my country's injection molding equipment is mainly used in the fields of home appliances, automobiles and general plastics. The broad application fields of plastic products provide strong growth potential for the prosperity of the injection molding machine industry.

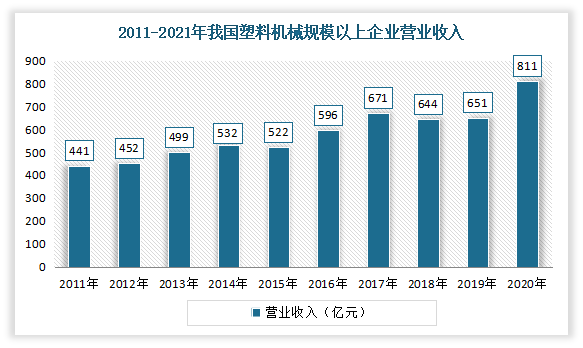

In recent years, with the rapid expansion of the application scope of plastic products, plastic machinery has become an important type of equipment. According to data from the China Plastics Machinery Industry Association, the operating income of China's plastic machinery enterprises above designated size reached 81.056 billion yuan in 2020, a year-on-year increase of 24.5%.

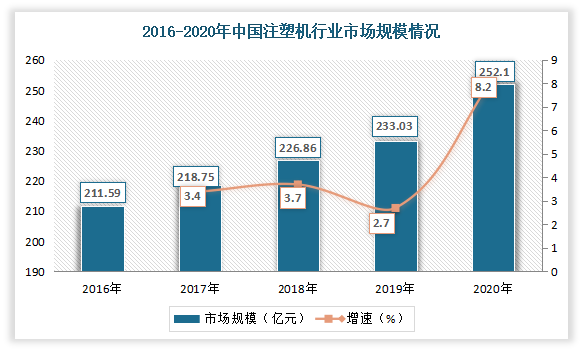

In recent years, with the development of lightweight automobiles, the upgrade of traditional home appliances such as refrigerators, washers, air conditioners, and paints, the rise of new home appliances such as air purifiers, vacuum cleaners, and sweeping robots, and the impact of the epidemic, plastics such as goggles, nucleic acid detection test tubes, and disposable syringes have The demand for medical supplies and life support equipment represented by ventilators has increased rapidly. The demand for injection molding equipment in my country has continued to grow, and the market size of injection molding machines has continued to expand. Data shows that the market size of my country's injection molding machine industry in 2020 is 25.21 billion yuan, a year-on-year increase of 8.2%.

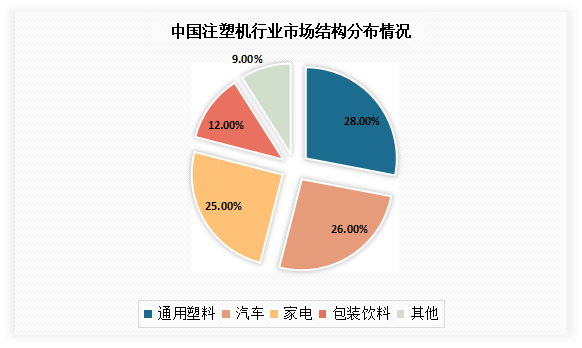

At present, automobiles, home appliances, packaging, general plastics and other fields are the main application fields of injection molding machines in my country. Among them, the general plastics field accounts for the highest proportion, accounting for 28%; followed by the automotive field, accounting for 26%.

Market competition landscape

Since the 1990s, with the realization of major breakthroughs in the range of processable raw materials, product types and complexity, product quality, equipment types, etc., injection molding technology has entered a stage of comprehensive application, development and innovation. However, compared with developed countries such as Europe, the United States, and Japan, my country's high-end equipment research and development and localization substitution have greater room for development. For example, European injection molding machine companies represented by Germany take the high-end and precision route, and their products have high technical content and added value; while my country's injection molding machine exports are mainly mid- to low-end models, and imported injection molding machines are mainly high-end.

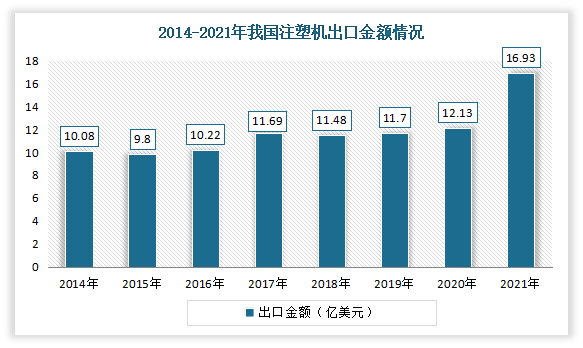

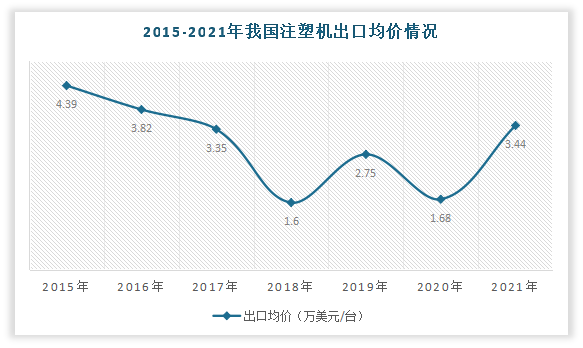

Against this background, my country's leading companies, represented by Haitian International, Yizumi and Chen Hsong, are catching up with the high-end market, gradually narrowing the international gap, and further expanding the global plastic machinery mayor/market share. According to statistics from the General Administration of Customs, in the third quarter of 2021, the total import and export volume of mainland China's 12 key tax code products for plastic machinery was close to US$4.375 billion, of which the export value was approximately US$2.725 billion, a year-on-year increase of 40%; throughout 2021, my country's injection molding The export value of machines was US$1.693 billion, 39.6% year-on-year; the average export price was US$34,400/unit.

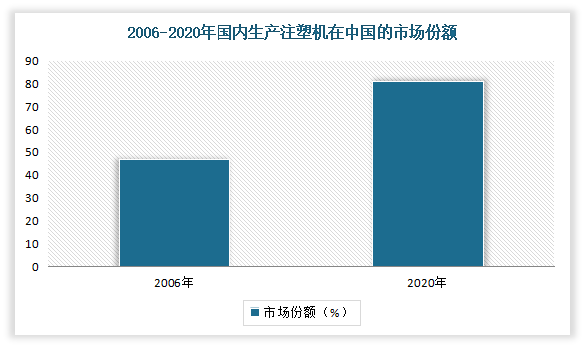

Although domestic injection molding machines are not competitive enough in the high-end market, they have basically occupied the mid- to low-end market share. With the construction of production bases by international brands in China and the rise of domestic enterprises, the domestic market share of injection molding machines produced in China has increased from 47% in 2006 to 81% in 2020. my country's injection molding machines have basically achieved localization.

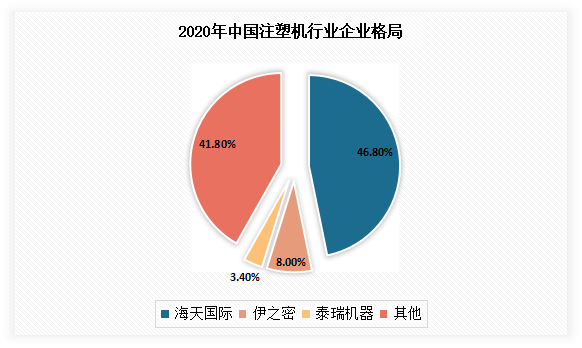

At present, my country's injection molding machine market is full of competition. Among them, Haitian International is the absolute leader in my country's injection molding machine market. It is in a relatively leading position in terms of scale and technology. It holds more than 40% of the market share of my country's injection molding machines. The market share of large injection molding machines is as high as 70~80%, ranking first in the country. echelon. Data shows that Haitian International's market share reached 46.8% in 2020, followed by Yizumi accounting for 8.0% and Terry Machinery accounting for 3.4%.

Development trend

The injection molding machine market will continue to grow in the future. First, in the field of downstream applications of injection molding machines, the lightweighting of automobiles has driven up the demand for automobile plastic products. As an important conservation resource, the continuous expansion of the application of plastics has also brought more development opportunities to injection molding machines. In addition, domestic injection molding machines rely on price advantages and continuous improvements in technology and quality, and their market share is expected to further increase, which will help the continuous development of China's injection molding machine industry.

Second, with the continuous transfer of the international industry in the injection molding machine industry, the injection molding machines produced in my country are also more widely recognized and accepted by the international market. In the future, the injection molding machines produced in my country will play an important role in the international industrial chain through the process of introduction, absorption, digestion, and re-innovation. International industrial transfer has increased the market demand for my country's injection molding machines and provided a broader market for my country's injection molding machine industry. room for development.

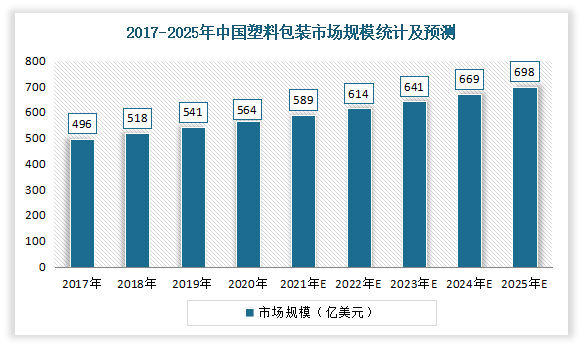

Third, my country is a major packaging manufacturing and consumer country in the world, and the packaging industry has been in a steady growth trend. The plastic packaging industry is an industry that continues to grow and develop globally. The proportion of my country's plastic packaging in the total output value of the packaging industry has exceeded 30%. China's plastic packaging market size was US$49.64 billion in 2017 and US$56.4 billion in 2020. It is expected to have an average annual compound growth rate of 4.4% by 2025. In the future, my country's plastic packaging industry market will have broad room for development, providing strong growth potential for the booming development of the injection molding machine industry.

Fourth, the injection molding machine industry has adopted servo power systems to improve the energy-saving effect of the hydraulic power system from the control principle and extend the service life of the injection molding machine. Servo control technology conforms to the trend of energy saving and consumption reduction, and will be more widely used in injection molding machines in the future. Servo systems have broad market prospects in the application of injection molding machines.

High efficiency and energy saving will become the main theme of development in the future. According to the "14th Five-Year Plan" plan and the outline of long-term goals for 2035, it is proposed to "create new advantages of the digital economy" and promote the deep integration of digital technology and the real economy. For traditional manufacturing industries, 2021 is the year when digital transformation officially begins. It is an important period for accelerating corporate management and product upgrades.

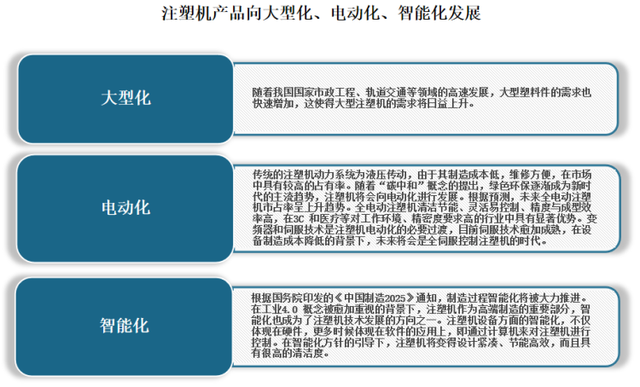

Large-scale, electrification and intelligence are the direction of product development. Although my country's injection molding machine companies have continuously improved their technology in the past two years, there is still a certain gap because they started later than developed countries abroad. Most companies still focus on the mid-to-low-end market. "The second version of large machines and small machine electrification" "The molding machine is the main form of development of my country's injection molding machine market. However, informatization, automation, and intelligence are already important directions and inevitable trends for the development of large enterprises. It is expected that as the technological and innovative advantages of my country's injection molding machine industry gradually become dominant, injection molding machine products will develop towards large-scale, electric and intelligent, and the development pattern of modern injection molding with sophisticated intelligence, low carbon and energy saving will also push Chinese technology to a greater level. On the stage, the trend of domestic substitution of imported goods is irreversible.

文章来源:观研天下

免责声明:所载内容、图片来源于互联网、微信公众号等公开渠道,我们对文中观点持中立态度,本文仅供参考、交流。转载的稿件版权归原作者和机构所有,如有侵权,请联系我们删除。

+86 186 6517 1961