In recent years, plastic has gradually replaced glass as the main material for vacuum blood collection tubes. Especially in the current environment, the demand for blood collection tubes is huge. According to statistics, its current global average annual demand reaches about 20 billion units, with a 10% growth rate far ahead of the overall growth of medical devices. Faced with such huge demand, more and more medical device manufacturers have established specialized injection molding workshops for plastic blood collection tubes, and there is an obvious demand for related automated production systems.

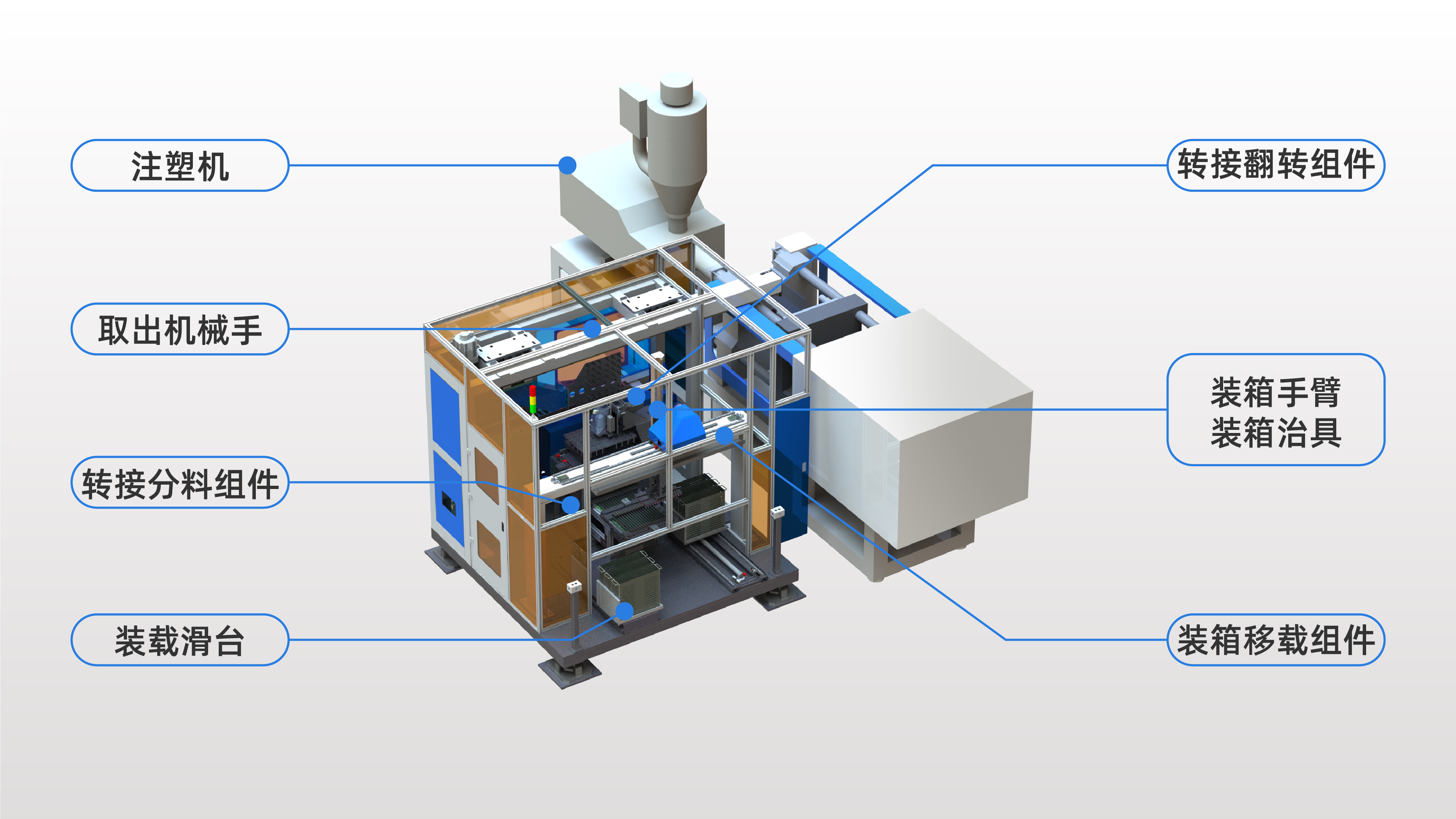

SWITEK's blood collection tube removal and packaging automation system mainly includes the following parts: removal manipulator, removal fixture, transfer and reversal/distribution component, packing arm/fixture, packing and transfer component, etc. The injection molding, removal and packaging of blood collection tubes are fully automated without manual labor. It can quickly help enterprises realize automated production, meet the requirements of clean and pollution-free medical equipment, reduce costs, increase efficiency, and create value.

Highlights of SWITEK blood collection tube removal and packaging automation system:

Reduce costs and increase efficiency: fully automatic packaging removal, saving manpower

High efficiency and quality assurance: stable structure, efficient production capacity, high yield rate

Safe cleaning: no manual intervention required to avoid contamination

Blood collection tube removal and packaging production case

Product: blood collection tube

Specification: 12*75mm

Material: PET

Injection weight: 180g

Product weight: 3.75g±0.1

Number of mold cavities: 48

Cycle period: 8S

Injection molding machine model: Demag Systec 280

+86 186 6517 1961